VIA Labs, Inc. (VLI) has expanded its connectivity portfolio with the introduction of its first industrial-grade USB 2.0 Hub controllers, the VL122 and VL123. The launch signifies the company’s strategic entry into industrial-grade applications, focusing on high-reliability design and long-term supply commitments for the embedded sector.

Engineered for stability in challenging thermal conditions, these controllers operate across an extended temperature range from -40°C to +85°C. The design emphasizes enhanced signal integrity and low power consumption, making the components suitable for integration into embedded systems, servers, industrial PCs, and smart retail terminals.

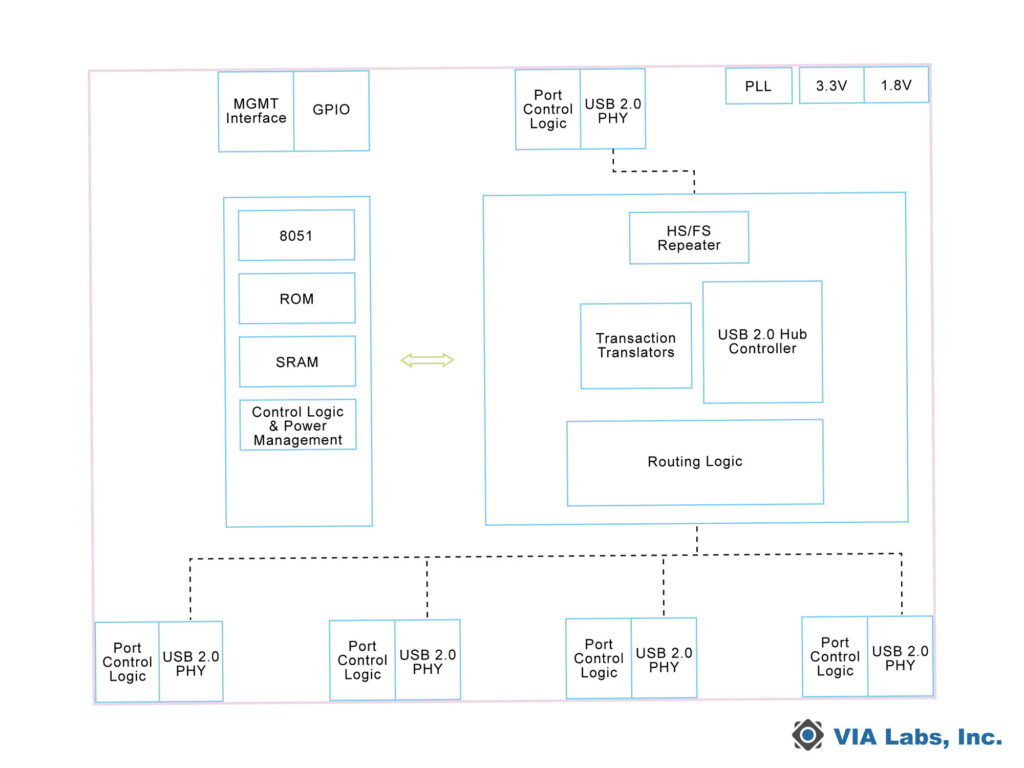

The VL122 is a 4-port USB 2.0 Hub controller that complies with the latest USB 2.0 specification updates from June 2025, including the DCR specification. It is housed in a compact QFN28 5×5 mm package and integrates a 5V-to-3.3V linear regulator. For system designers requiring customization, the VL122 supports configuration management via SMBus or EEPROM, allowing for the adjustment of VID/PID and individual port electrical settings. The component has obtained USB-IF USB 2.0 Hub certification and is available in both commercial and industrial grades, with optional unique serialization for supply chain traceability.

Scheduled for release in the second quarter of 2026, the VL123 will provide a pin-compatible alternative featuring a Multiple Transaction Translator (MTT) architecture. This architecture is designed to improve throughput when multiple USB full-speed devices are operating simultaneously.

Regarding the development process, Tony Ho, Senior Director of Product and Manufacturing Engineering at VLI, stated: “VLI has established a comprehensive industrial-grade product reliability verification process from product specification definition to quality- and reliability-driven processes through layout implementation. The key design IP and full-chip system validation are compliant with international electronic environmental stress testing standards.”

To maintain these standards, the company utilizes a dedicated in-house verification facility. “VLI has established a complete in-house product verification laboratory. High-coverage self-debug test vectors and specialized equipment characterize the electrical performance limits and tolerances of the device under test, ensuring the lowest DPPM in customer applications. We collect and continuously monitor certified test data from our manufacturing and testing partners to ensure strict quality control,” added Ho.

The new line of controllers will be showcased at CES 2026 in Las Vegas.